+86 15633683072

Choosing a robotics supplier sounds simple—until you realize that not all robotic systems integration is built on the same engineering logic.

An integrator experienced in packaging lines may excel at deploying an automated palletizing system, but that does not automatically qualify them to design a stable robotic arm for welding solution. The physics, risk profile, and long-term maintenance logic are completely different.

If you are investing in welding automation, understanding this difference can save you years of frustration.

On paper, both welding and palletizing use robots. In practice, they demand opposite integration philosophies.

Robotic systems integration for palletizing focuses on:

Payload and reach

Box pattern algorithms

End-of-arm tooling change

Conveyor synchronization

Throughput per hour

By contrast, robotic systems integration for welding revolves around:

Arc stability and power source matching

Seam tracking and gap compensation

Heat distortion management

Fixture rigidity

Metallurgical repeatability

An integrator who primarily builds automated palletizing robot lines thinks in terms of stacking logic. A welding integrator thinks in terms of molten metal behavior.

A palletizing cell is mechanically predictable. Boxes don’t warp under heat. Pallets don’t shrink due to thermal input.

A robotic arm for welding, however, interacts with a process that changes the workpiece in real time.

When selecting an integrator for a robotic arm for welding, you should ask:

How do they manage weld deformation across long seams?

How do they ensure TCP accuracy after fixture replacement?

How do they coordinate the robotic arm welding machine with the power source waveform?

What is their solution for root gap variation?

These are not questions typically addressed in an automated palletizing system project.

A palletizing integrator optimizes motion efficiency.

A welding integrator must control metallurgy, mechanics, and motion simultaneously.

A robotic arm welding machine is not just a robot with a torch attached.

Proper robotic systems integration for welding includes:

Power source selection (pulse, tandem, CMT, etc.)

Wire feeding stability under continuous duty cycles

Torch cooling strategy

Welding position strategy (flat, horizontal, vertical)

Multi-layer programming logic

In contrast, an automated palletizing robot mainly requires reliable gripping and stacking accuracy.

Both are automation—but only one involves molten steel at 6,000°C.

When evaluating robotic systems integration, you need to determine whether the integrator understands arc characteristics—or only motion curves.

From the outside, welding and palletizing both fall under industrial robotic solutions.

But the operational risk profile is dramatically different:

| Palletizing | Welding |

|---|---|

| Predictable payload | Variable heat distortion |

| Minimal safety exposure | Arc radiation & fumes |

| Standard EOAT | Custom welding torches |

| Simple path logic | Complex seam trajectories |

An automated palletizing system failure usually means downtime.

A poorly integrated robotic arm for welding means scrap, rework, structural failure, or safety hazards.

That is why robotic systems integration experience in welding environments must go beyond general automation knowledge.

One of the biggest hidden differences: fixture philosophy.

For palletizing:

The product is already finished.

Positioning tolerance is wide.

For welding:

The fixture defines seam alignment.

Clamping sequence affects weld penetration.

Thermal expansion must be absorbed mechanically.

A true welding-focused robotic arm for welding integrator engineers the fixture before programming the robot.

A palletizing integrator often programs first and adapts mechanically later.

That inversion alone can define whether your robotic arm welding machine produces stable welds or inconsistent seams.

Many automation companies market themselves broadly. They claim competence in everything from automated palletizing robot solutions to welding cells.

The critical difference is field experience.

Ask:

How many robotic arm welding machine lines have they commissioned?

Have they handled multi-station welding production lines?

Do they understand weld parameter validation?

Can they debug porosity and lack-of-fusion issues?

If their portfolio is dominated by automated palletizing system installations, their risk model is not built around welding complexity.

Welding automation is not about installing a robot—it is about stabilizing a process.

True robotic systems integration for welding includes:

Welding procedure qualification alignment

Robot-path-to-seam calibration under real production conditions

Power source–robot communication protocols

Arc start reliability testing under batch production

A general integrator may deliver a working cell.

A welding specialist delivers a production-ready system.

That difference becomes visible after the first 10,000 parts—not on acceptance day.

We are not a packaging integrator that occasionally installs welding robots.

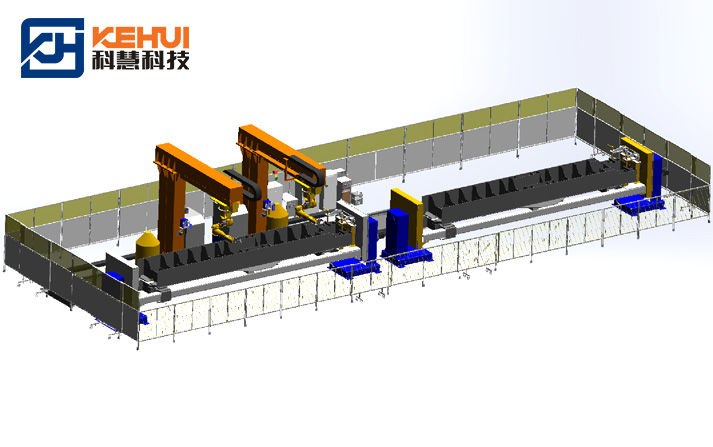

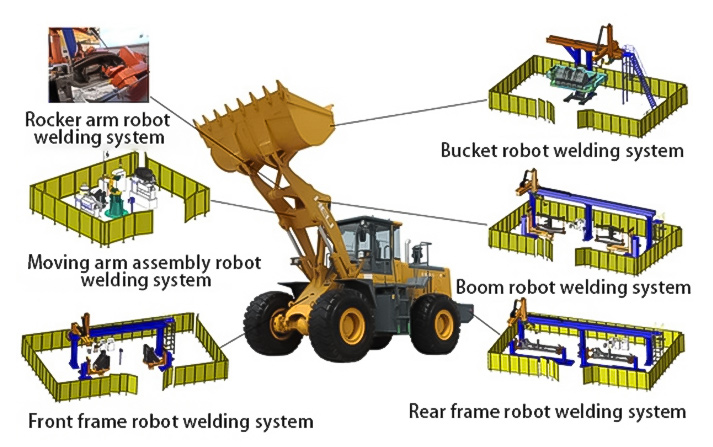

Since 1994, we have focused on welding-centered robotic systems integration, delivering:

Robotic arm for welding workstations

Multi-station robotic arm welding machine production lines

Fully integrated industrial robotic solutions for heavy manufacturing

On-site commissioning and training worldwide

Our engineers do not just install robots—they validate weld parameters under real production loads.

We design fixtures and welding sequences together.

We match power sources to material behavior.

We build systems that can run three shifts without arc instability becoming tomorrow’s problem.

Our robotic arm for welding systems are exported globally, supporting industries such as construction machinery, structural steel, pressure vessels, and heavy fabrication.

When you compare integrators for welding versus palletizing, the question is not who can install a robot.

The question is:

Who understands what happens after the arc starts?

If your priority is long-term weld stability, scalable production lines, and practical on-site engineering support, then choosing a welding-focused robotic systems integration partner is not optional—it is strategic.

And that is exactly what we have been building for over three decades.

Zhengzhou Kehui Technology Co., Ltd

Email: info@zzkehui.com